We strive to keep up with the latest strictest requirements of woven polypropylene bags from case study to ensure our customers receive high quality international standard packaging bags. PP and PE resin the input materials for bag production. Pp woven bag production process

Pp Woven Bag Production Process, 11653 1986 For polypropylene PP woven sacks for packing cement withdrawn superseded by IS 11652. Woven fabrics coated with compound materials and paper or film are compounded or coated. Non-woven bag production process. We specialized in manufacturing BOPP laminated woven packagings which is widely us.

Quality Production Process Z Pack From zpackbd.com

Quality Production Process Z Pack From zpackbd.com

Changying Plastic Woven Packaging Co Ltd is located in Dongguan China. Manufacturing of woven bags machine has high quality steady production process and incorporate technology that produce PPHDPE bags and sacks. Non-woven bag production process. Before bag construction begins however the material must be woven and cut.

Production process of composite plastic woven bags.

Read another article:

Pp woven bags manufacturing process. PP woven bag processing machinePolystar Taiwan - Original manufacturer of PP woven bag processing machineSend your inquiry for PP woven bag processing mach. RecoSTAR universal the state-of-the-art extrusion and pelletising system for all types of woven bag production waste delivers high quality regranulate. The various type of PP bags commonly in practice. The first step involves extrusion where a mix of virgin ingredients are melted and.

PP and PE resin the input materials for bag production. The various type of PP bags commonly in practice. Black card plus gold stamping can make your bag look more upscale. Ulinkpack is a 20 years experienced PP material based manufacturer in China. 2.

Source: starlinger.com

Source: starlinger.com

It is then slit into tape yarn by the slitting unit and stretched and annealed. We specialized in manufacturing BOPP laminated woven packagings which is widely us. The first step involves extrusion where a mix of virgin ingredients are melted and. The product has good black degree uniform. Packaging Starlinger.

Source: tf-machinery.com

Source: tf-machinery.com

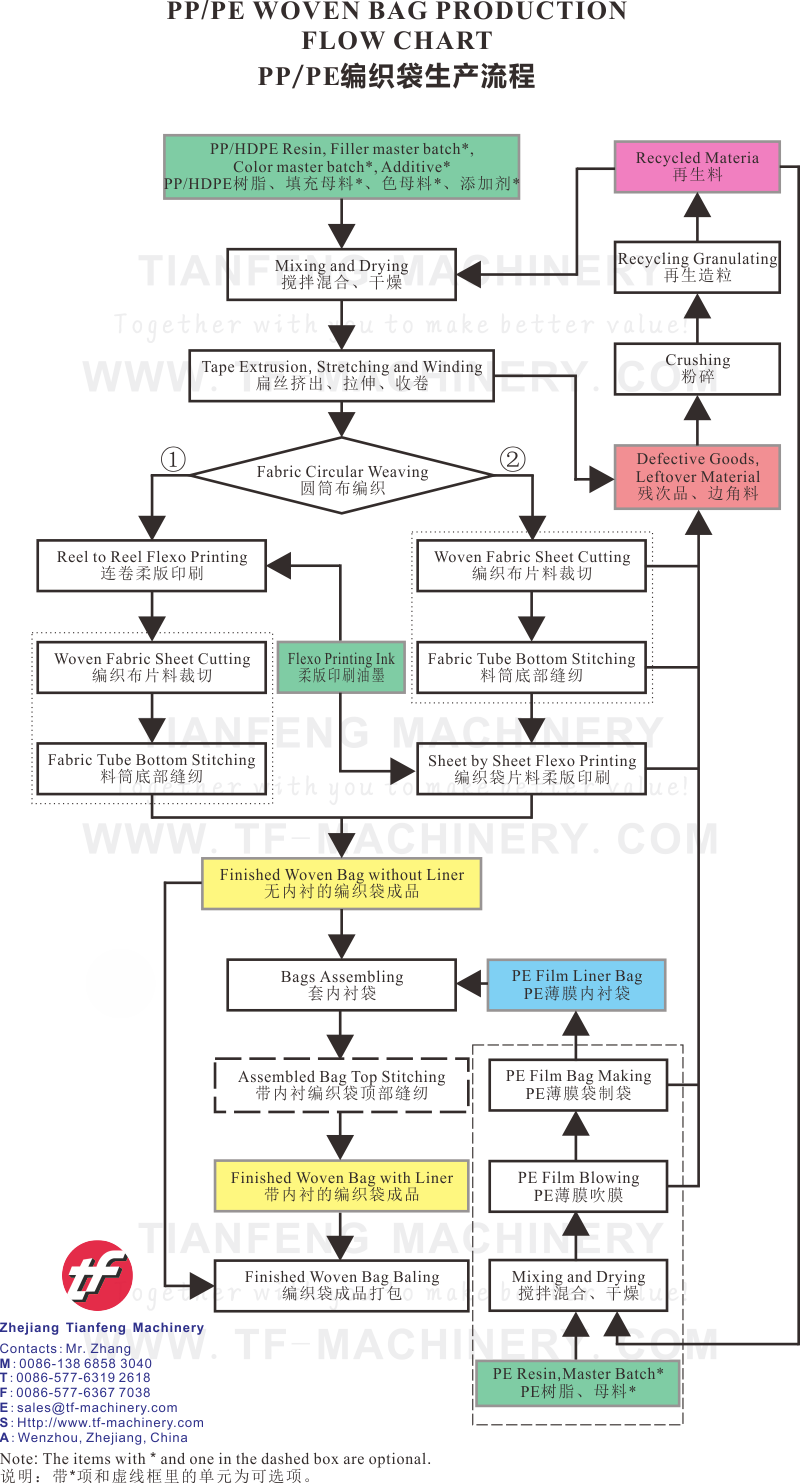

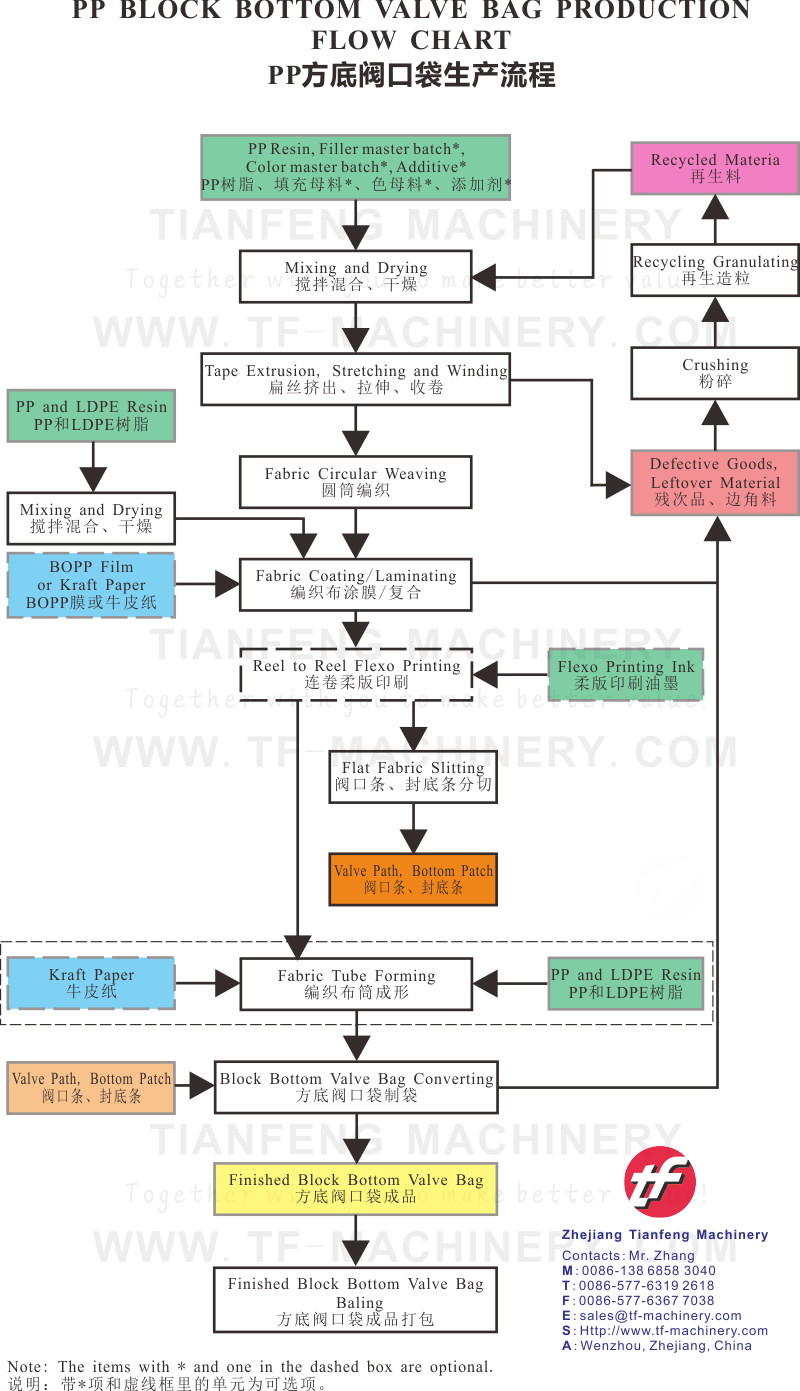

11653 1986 For polypropylene PP woven sacks for packing cement withdrawn superseded by IS 11652. Knowing the bag production process as no other. PP Woven Sacks are generally manufactured and printed as per the Customers demandsneeds. Various Type of HDPEPP Bags. 1 Pp Pe Woven Bag Production Line Plastic Weaving Products Production Flow Chart Tianfeng Machinery Professional Manufacturer Of Plastic Flexible Woven Products Machinery Pp Woven Bag Production Line Pp Block Bottom Valve Cement Bag Sack.

Source: zpackbd.com

Source: zpackbd.com

Pp woven bags manufacturing process. Ulinkpack is a 20 years experienced PP material based manufacturer in China. The various type of PP bags commonly in practice. Pp Woven Bags Raffia The Concept And Process. Quality Production Process Z Pack.

Source: sapphirevn.com

Source: sapphirevn.com

It is produced on a loom and made of many threads woven on a warp and a weft. We specialized in manufacturing BOPP laminated woven packagings which is widely us. MornPackaging As one of the leading manufacturers of pp woven bagsfabric in ChinaWe are offering a complete process of pp woven bags manufacturing service main process includes pp extruding circular weaving flexo printing gravure printing lamination bags cutting LDPEHDPE inserting gusseting bags sewing etc. The first step involves extrusion where a mix of virgin ingredients are melted and. The Complete Guide To Pp Woven Sacks Sapphire Packaging Co Ltd Reusable Shopping Bag Manufacturer.

Source: wovenpp.com

Source: wovenpp.com

PP Woven Bags Fabric. The development trend of bag-making filling and sealing packaging machinery is modular structure multi-row high-speed high stability simple transmission mechanism self-adaptive closed-loop control which is suitable for the production of pp woven sugar bags. The process of manufacturing bulk bags can be broken down into the following 11 steps. PP and PE resin the input materials for bag production. Manufacturing Process Of Pp Woven Bags Morn Packaging Co Ltd.

Source: royaltouchfablon.com

Source: royaltouchfablon.com

All pp woven bags manufacturing process wholesalers pp woven bags manufacturing process manufacturers come from members. Third processing equipment for metal packaging containers. PP woven bag PP valve bag paper sack square bottom woven. Polypropylene woven bag production process polypropylene woven bag complete production line includes. Regarding Queries Of Pp Woven Bag Manufacturer In India.

Source: chinawovenbag.com

Source: chinawovenbag.com

Polypropylene woven bag production process polypropylene woven bag complete production line includes. Manufacturing of woven bags machine has high quality steady production process and incorporate technology that produce PPHDPE bags and sacks. PP woven bag PP valve bag paper sack square bottom woven. Production process 1- Extrusion The first step is extrusion where to a mix virgin PP resin UV Master Batch Calcium carbonate and colour pigment is melted and shaped into tapes in an Extrusion machine. Woven Bags Process Of Fabric Weaving Part Two.

Source: gpl.co.in

Source: gpl.co.in

It is then slit into tape yarn by the slitting unit and stretched and annealed. We specialized in manufacturing BOPP laminated woven packagings which is widely us. Production process 1- Extrusion The first step is extrusion where to a mix virgin PP resin UV Master Batch Calcium carbonate and colour pigment is melted and shaped into tapes in an Extrusion machine. The process of manufacturing PP woven bags involves mixing raw materials starting with PP or HDPE pellets and other additives extruding the raw materials into a yarn PP resin is heated with feeler of CaCo3 and pigment melted and extruded as a flat film. Pp Woven Sack Manufacturing Process Ganpati Plastfab Limited.

Source: wovenpp.com

Source: wovenpp.com

The first step involves extrusion where a mix of virgin ingredients are melted and. The process of manufacturing PP woven bags involves mixing raw materials starting with PP or HDPE pellets and other additives extruding the raw materials into a yarn PP resin is heated with feeler of CaCo3 and pigment melted and extruded as a flat film. According to customers quality requirements different raw material ratios can be selected. PP woven bag processing machinePolystar Taiwan - Original manufacturer of PP woven bag processing machineSend your inquiry for PP woven bag processing mach. Production Process Of Polypropylene Weaving And Pp Woven Bags Making Morn Packaging Co Ltd.

Source: wovenpp.com

Source: wovenpp.com

We strive to keep up with the latest strictest requirements of woven polypropylene bags from case study to ensure our customers receive high quality international standard packaging bags. Woven polypropyleneHDPE bags or s. The product has good black degree uniform. We doesnt provide pp woven bags manufacturing process products or service please contact them directly and verify their companies info carefullypp woven bags manufacturing process products or. Production Process Of Polypropylene Weaving And Pp Woven Bags Making Morn Packaging Co Ltd.

Source: tf-machinery.com

Source: tf-machinery.com

Manufacturing of woven bags machine has high quality steady production process and incorporate technology that produce PPHDPE bags and sacks. Woven fabric is a textile formed by weaving. PP woven bag processing machinePolystar Taiwan - Original manufacturer of PP woven bag processing machineSend your inquiry for PP woven bag processing mach. The various type of PP bags commonly in practice. 3 Pp Block Bottom Valve Bag Production Line Plastic Weaving Products Production Flow Chart Tianfeng Machinery Professional Manufacturer Of Plastic Flexible Woven Products Machinery Pp Woven Bag Production Line Pp Block Bottom Valve.

Source: chinawovenbag.com

Source: chinawovenbag.com

Various Type of HDPEPP Bags. Before bag construction begins however the material must be woven and cut. Non-woven bag production process. Different Types of Plastics and Their Classifications. Woven Bags Process Of Fabric Weaving Part Two.

Source: gpl.co.in

Source: gpl.co.in

Ulinkpack is a 20 years experienced PP material based manufacturer in China. RecoSTAR universal the state-of-the-art extrusion and pelletising system for all types of woven bag production waste delivers high quality regranulate. The product has good black degree uniform. For make all you dear customers a better understanding of how to make a pp. Pp Woven Sack Manufacturing Process Ganpati Plastfab Limited.

Source: pinterest.com

Source: pinterest.com

We strive to keep up with the latest strictest requirements of woven polypropylene bags from case study to ensure our customers receive high quality international standard packaging bags. The development trend of bag-making filling and sealing packaging machinery is modular structure multi-row high-speed high stability simple transmission mechanism self-adaptive closed-loop control which is suitable for the production of pp woven sugar bags. Drying mixer drawing unit winding machine circular loom printing machine bag cutting machine sewing machine. The end users adopt different kinds of Colour Combinations and Designs in the Printing of these Sacks to convey the massages characteristics quantity quality related details and. Pp Woven Bags Manufacturer Supplier Dns Group Woven Bag Woven Jute Bags.